Application And Advantages Of Truss Robot for Turning Metal Processing

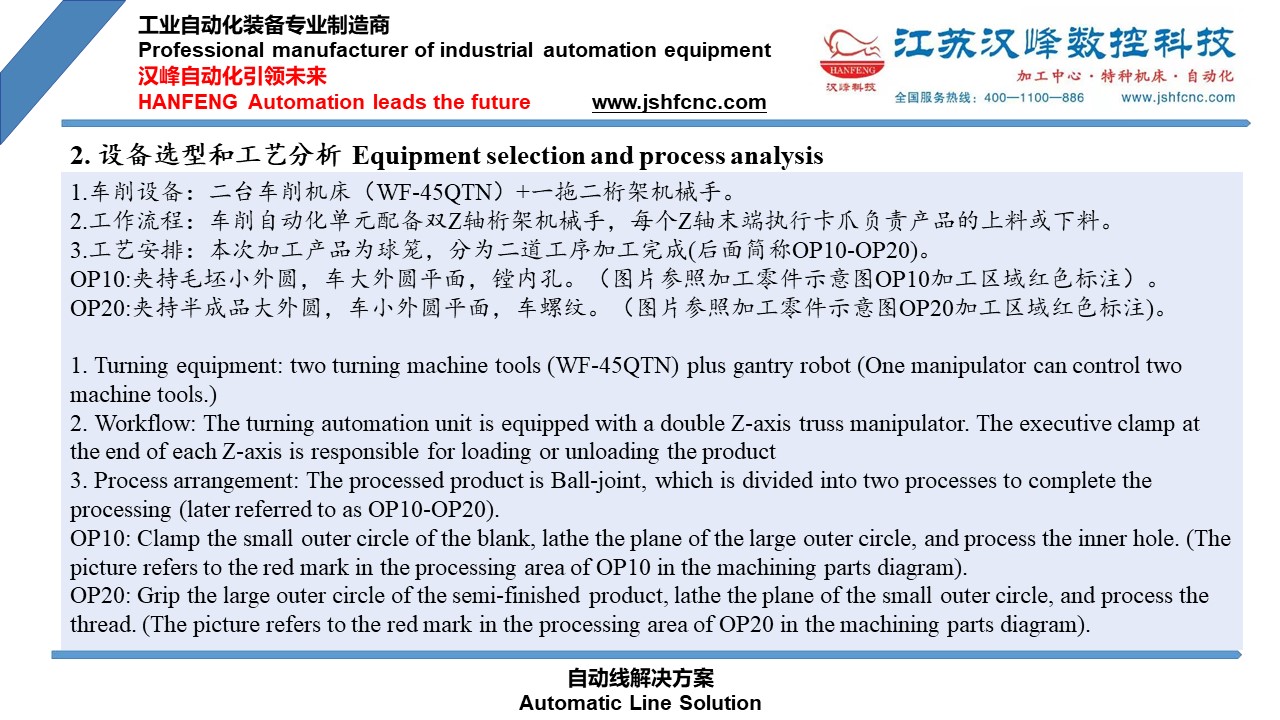

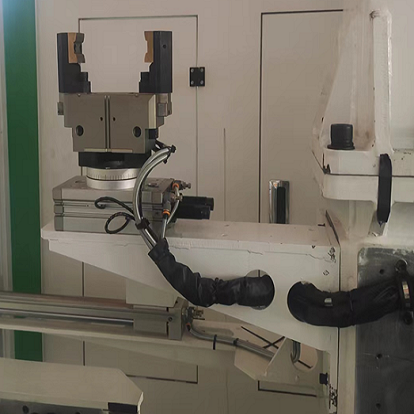

1.When the machine tool is operated manually, it is necessary to first remove the processed parts from the machine tool, put them in the material bin outside the machine tool, and then put the blanks in. The turning automation unit is equipped with a double Z-axis truss manipulator. When the Z-axis end clamps the blank into the lathe, the other clamp first clamps the processed parts, and then feeds the blanks in. The machine tool does not need to wait for loading. The loading and unloading time of the truss is 15S. If the processing time of the parts is within 15S, the truss does not need to wait.

2.Z and X move in two axes, and the space angle between each degree of freedom is nght.

3.It is controlled by a special system and can be programmed repeatedly. All the movements are programmed.

4.Feeding, loading and unloading are all protected, and the work can be stopped automatically under vanous abnormal conditions. To prevent collision of machine tools and manipulators.

5.Flexible and multi-functional, which can be replaced quickly and easily according to different parts (fixture, grip, mounting frame, etc.).

6.High reliability, high speed, high precision, simple operation and maintenance.

7.Surtable for two or more processes between the workpiece transfer, using special control High positioning accuracy and high speed.

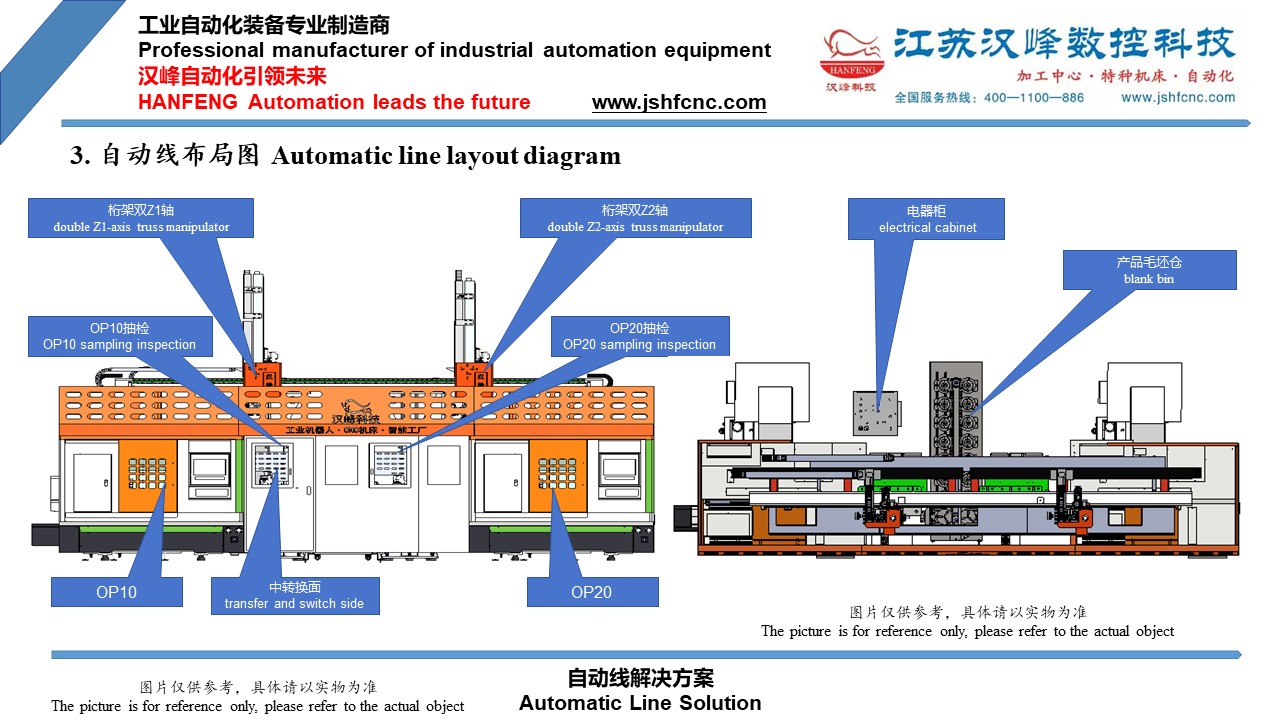

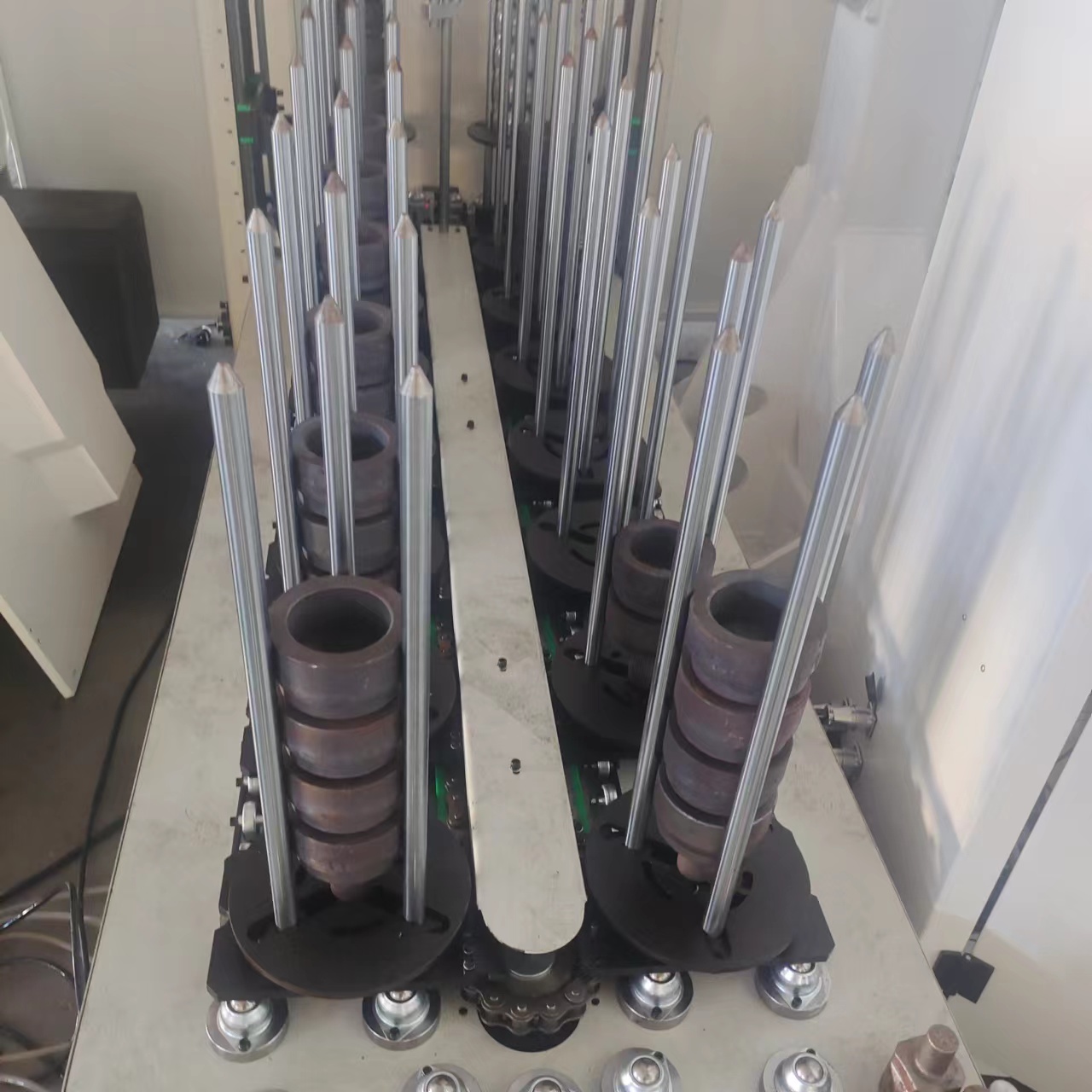

Workshop site

Blank bin

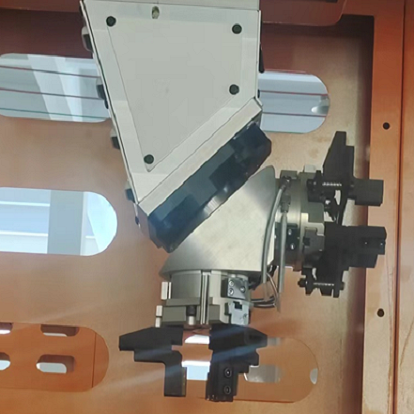

Double Z2-axis truss manipulator Transfer and switch side