In order to cope with complex tasks and achieve high-level surface quality and efficient production, the VM excellent machining center came into being. For this reason, we have used a new and higher standard design, which not only improves production efficiency, but also ensures high precision and reliable stability of the product.

10.Complete automation equipment canwith Hanfena's WFR series industrial robots to form an automatic processing unit.

Applications

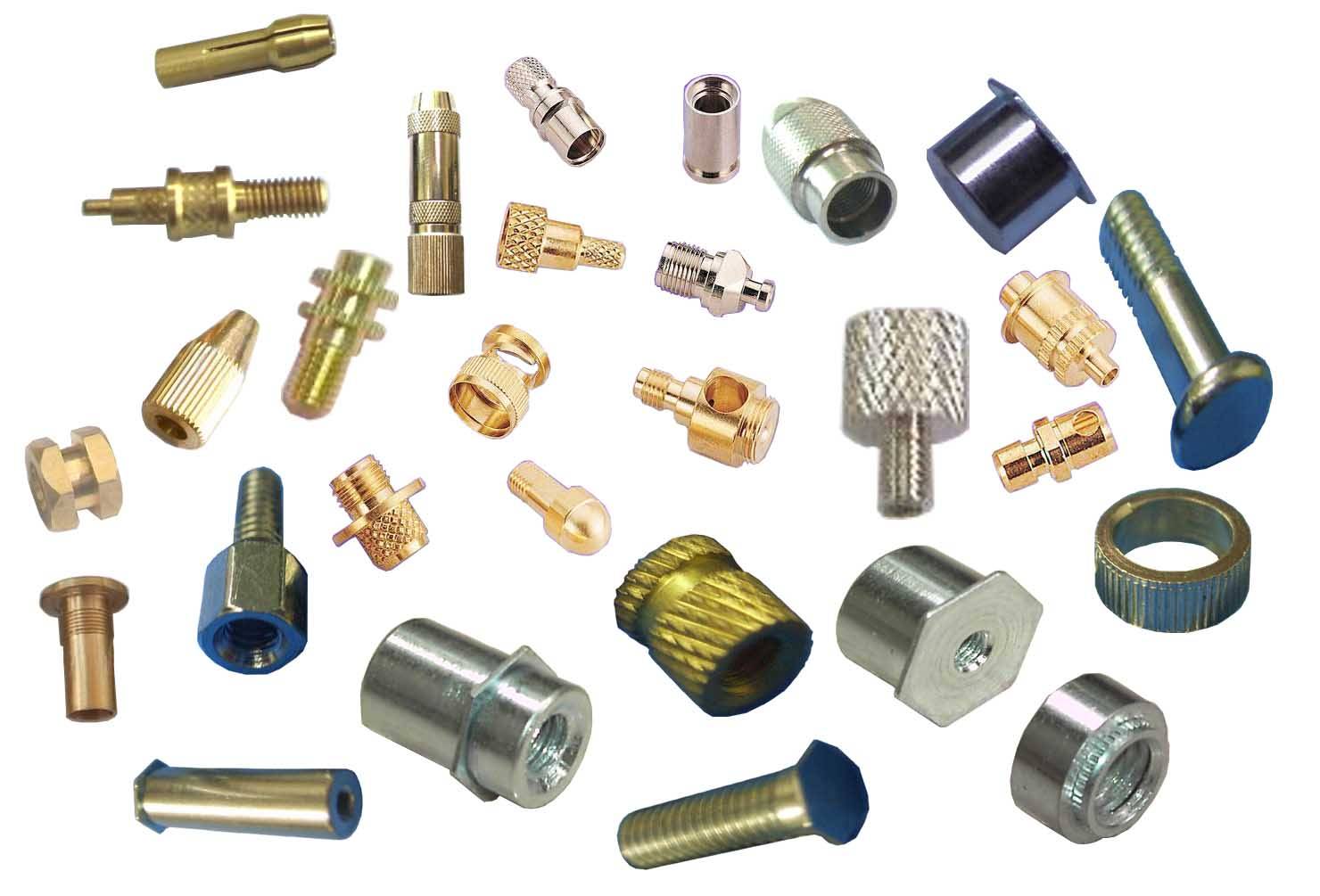

1. Shaft components: CNC lathes are capable of machining a range of shaft components such as transmission shafts, drive shafts,and crankshafts with high precision and efficiency.

2. Valve components: CNC lathes have the ability to machine valve components such as valve bodies, valve stems, and valve seats with high precision and tight tolerances.

3. Aerospace components: CNC lathes can be used to machine complex aerospace components such as engine components, landing gear components, and flight control components.

4. Electrical components: CNC lathes can be used to machine electrical components such as connectors, terminals, and conductive components with high accuracy and quality.

5. Medical components: CNC lathes can be used to create precise medical components such as surgical instruments, dental implants, and prosthetics.

6. Automotive components: CNC lathes are widely used in the automotive industry to manufacture components such as bearings,axles, and gears.

7. Hydraulic components: CNC lathes are capable of producing high-precision hydraulic components such as cylinders, pistons, and pump parts.

8. Mold components: CNC lathes are commonly used to produce mold components such as core pins, ejector pins, and cavity inserts with precision and efficiency.

9. Precision gears: CNC lathes are ideal for manufacturing precision gears such as spur gears, helical gears, and bevel gears with high accuracy and repeatability.

10. Sports equipment components: CNC lathes can be used to manufacture a variety of sports equipment components such as golf club heads, bicycle parts, and fishing reels.

Processing Case

Company Information

Jiangsu Hanfeng CNC Technology Co., Ltd. takes intelligent manufacturing as the core mission, integrates independentresearch, design and producton, as wel as focuses on the integration of intelligence, automation, and intormation resourcesBased on product quality and service satisfaction, jiangsu Hanfeng CNC Technology Co..Ltd is also a national high-techenterprise specialized in the research, production and sales of CNC lathes, industrial robots and factory automationequipment. it strives to accomplish his mission with creating high quality, high efficiency, high value and low energyconsumption for customers.

Since its establishment, the company has been commited to the research of CC products and technologicalbreakthroughs. The research team has mastered research and manufacturing experience for many years in intelligenautomated industrial robot field. Hanfeng also carries out in-depth strategic cooperation with some European enterprises andother research institutions in China. The main product includes: CNC lathes, CNC machining centers, truss robot, andarticulated arm robot, etc., which are applicable to aerospace, metallurgy, automoble industry, ral transit, education, medicatreatment, construction machinery, clean energy, machine tools, tools and defense industry etc. Hanfeng Technology hasbecome a powerful promoter and participant in the national defense industry. With the ideal of serving the country byindustry, Hanfeng Technology makes continuous contributions to strengthening national industry, bullding a strong countrywith intelligence, and serving the era of 'strong, rich, beautiful and high-tech'.

Workshop Display

Our Certificate

Package&Transport

FAQ

1. How do you package?

According to the size of the machine tool and container specifications, small machine tools usewrapping film and customized wooden boxes, while large machine tools use wrapping film.

2. How should l pay for my order?

You need to pay 30% of the payment first before we can start production. After the machine iscompleted, we will send you pictures or videos, and you will need to pay the balance beforeshipping.

3. How long is the delivery time?Regular Machines,We will delivery then within 20 working days after received your deposit,if somespecial machines will be some longer.we will give you the answer accordingly.

4.What is your minimum order quantity and warranty?

MOQ is 1 set, and warranty is one year.

5.What is your trade terms?

FOB,CFR, ClF or others terms are all acceptable.