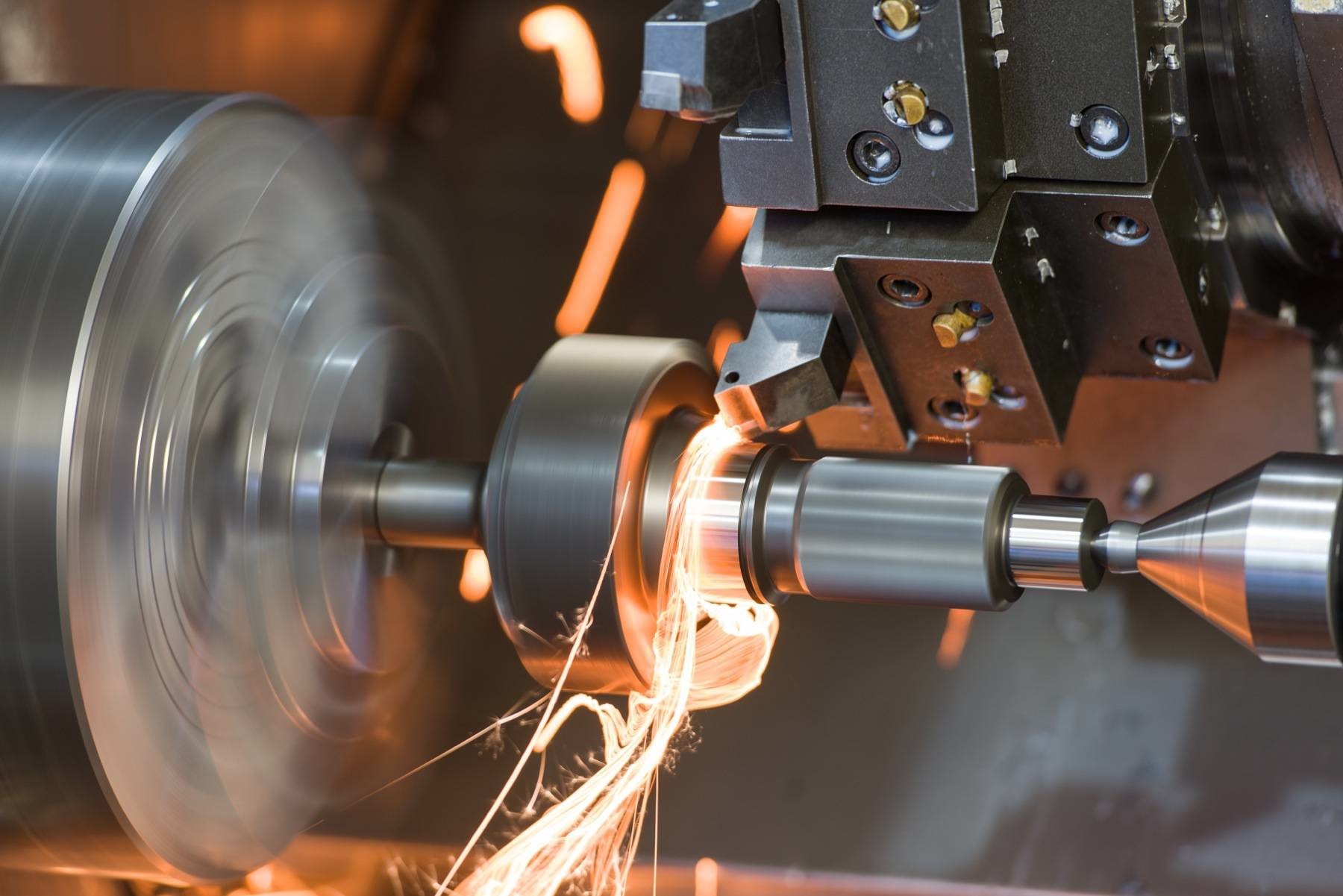

The inclined CNC lathe is a high-precision, high-efficiency automated machine tool. Equipped with a multi-station turret or a powered turret, the machine tool has a wide range of processing capabilities. It can process linear cylinders, oblique cylinders, arcs and various threads, grooves, worms and other complex workpieces. It has linear interpolation, arc Interpolates various compensation functions and plays a good economic role in the mass production of complex parts. Lathe linear rolling guides meet high-speed requirements, reduce friction resistance and temperature rise deformation, improve processing accuracy, and ensure the long-term stability of cutting accuracy. The tool detection device can automatically input the tool tip position data into the CNC system, greatly reducing the adjustment time when changing tools, and can also automatically compensate for the wear of the tool tip.

The inclined CNC lathe is a high-precision, high-efficiency automated machine tool. Equipped with a multi-station turret or a powered turret, the machine tool has a wide range of processing capabilities. It can process linear cylinders, oblique cylinders, arcs and various threads, grooves, worms and other complex workpieces. It has linear interpolation, arc Interpolates various compensation functions and plays a good economic role in the mass production of complex parts. Lathe linear rolling guides meet high-speed requirements, reduce friction resistance and temperature rise deformation, improve processing accuracy, and ensure the long-term stability of cutting accuracy. The tool detection device can automatically input the tool tip position data into the CNC system, greatly reducing the adjustment time when changing tools, and can also automatically compensate for the wear of the tool tip.The principle and solution of excessive temperature of the guide bearing of inclined CNC lathe:

1. Reasons for the increase in temperature of guide bearings

1. The contact points on the surface of the shaft ceramic tile are small and the contact surface is insufficient, which does not meet the equipment specifications.

2. The increase in the clearance of the guide bearing is much larger than the clearance required by the design, which makes it difficult for the lubricating oil to form an oil wedge when it enters the bearing tile surface, causing poor lubrication, causing the temperature of the guide bearing to rise and the vibration of the unit to increase.

2. Solutions to the increase in temperature of guide bearings

1. When the CNC lathe is running continuously, the temperature of the cooling water should not exceed 25°C, and the maximum temperature of the ceramic tile temperature and the oil temperature should not exceed 65°C. Changes in wattage and oil temperature are not only related to the temperature of the cooling water, but also to the circulation of lubricating oil and the clearance between the spindle shaft and journal.

2. The allowable clearance of the guide bearing of the inclined guide CNC machine tool is 0.2~0.3mm (two-way clearance), and the lower part of the bearing is immersed in lubricating oil. When the spindle rotates clockwise, lubricating oil can easily enter the bearing surface of the guide bearing and create an oil wedge. When lubricating the ceramic tile surface, even through the large swing point of the spindle, although the matching gap is small, due to the short distance, good lubrication conditions, less heat generated by friction, and good cooling effect, generally it will not cause the bearing temperature rise phenomenon, nor will it cause Tile burning.