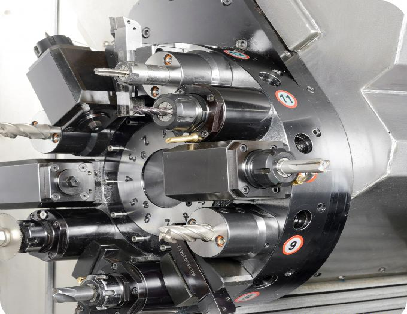

The application of CNC technology and CNC machine tools has successfully solved the automation problems of certain medium and small batches of parts with complex shapes and high consistency requirements. This not only greatly improves production efficiency and processing accuracy, but also reduces the labor intensity of workers. The production preparation cycle is shortened. However, during the use of CNC lathes, various faults will inevitably occur with CNC lathes, so the repair of faults has become the most critical issue for CNC lathe users. On the one hand, the after-sales service of the sales company cannot be guaranteed in time. On the other hand, mastering some maintenance techniques can quickly determine the location of the fault, shorten the maintenance time, and get the equipment running as soon as possible. In daily failures, we often encounter tool holder, spindle, thread processing, system display, drive, communication and other failures. Tool holder failure accounts for a large proportion of them. Here, we will introduce various types of four-station electric tool holder failures encountered in daily work and their corresponding solutions. I hope it can provide you with some useful reference. The CNC system used is the GSK series lathe CNC system produced by Guangzhou CNC Equipment Co., Ltd.

The application of CNC technology and CNC machine tools has successfully solved the automation problems of certain medium and small batches of parts with complex shapes and high consistency requirements. This not only greatly improves production efficiency and processing accuracy, but also reduces the labor intensity of workers. The production preparation cycle is shortened. However, during the use of CNC lathes, various faults will inevitably occur with CNC lathes, so the repair of faults has become the most critical issue for CNC lathe users. On the one hand, the after-sales service of the sales company cannot be guaranteed in time. On the other hand, mastering some maintenance techniques can quickly determine the location of the fault, shorten the maintenance time, and get the equipment running as soon as possible. In daily failures, we often encounter tool holder, spindle, thread processing, system display, drive, communication and other failures. Tool holder failure accounts for a large proportion of them. Here, we will introduce various types of four-station electric tool holder failures encountered in daily work and their corresponding solutions. I hope it can provide you with some useful reference. The CNC system used is the GSK series lathe CNC system produced by Guangzhou CNC Equipment Co., Ltd.Fault phenomenon 1: The electric tool holder is not locked tightly

① The position of the sending disk is not aligned: Remove the top cover of the tool holder, rotate and adjust the position of the sending disk, and align the Hall element of the tool holder with the magnet so that the tool stops at the correct position.

② The system anti-lock time is not long enough: just adjust the system anti-lock time parameters (the new tool post anti-lock time t=1.2s).

③ Mechanical locking mechanism failure: Disassemble the tool holder, adjust the machine, and check whether the positioning pin is broken.

Fault phenomenon 2: A certain tool number of the electric tool holder does not stop rotating, but the other tool positions can rotate.

① The Hall element of the tool at this position is damaged: Confirm which tool position causes the tool holder to rotate continuously, enter a command on the system to rotate the tool position, and use a multimeter to measure whether there is a voltage change between the signal contact of the tool position and the +24V contact. , if there is no change, it can be determined that the Hall element of the bit knife is damaged, and the sending disk or Hall element should be replaced.

② The tool position signal line is broken, causing the system to be unable to detect the in-position signal: Check whether there is a break in the connection between the tool position signal and the system, and connect it correctly.

③ There is a problem with the system's tool position signal receiving circuit: When it is determined that there is no problem with the Hall element of the tool position and that there is no problem with the connection between the tool position signal and the system, replace the main board.